Hanford leaking tanks

Energy announced in April 2021 — following a year-long leak assessment — that Tank B-109 is leaking toxic, radioactive nuclear waste into the soil. This waste can find its way into groundwater over time and eventually reach the Columbia River. Tank B-109 is the second tank known to be actively leaking — Tank T-111 was found to be leaking in 2013.

On Aug. 15, 2024, Energy announced another tank, T-101, is likely leaking and declared it an “assumed leaker." In November 2024, the agencies included T-101 into the Agreed Order in the form of an addendum.

We issued an Agreed Order in 2022 with the U.S. Department of Energy (Energy), that defines a plan for how to respond to B-109 and T-111. The order also requires Energy to develop a plan for how to respond to any future tank leaks at the Hanford Site. In November 2024 we issued an addendum to the Agreed Order to incorporate another leaking tank, T-101, into the order’s requirements.

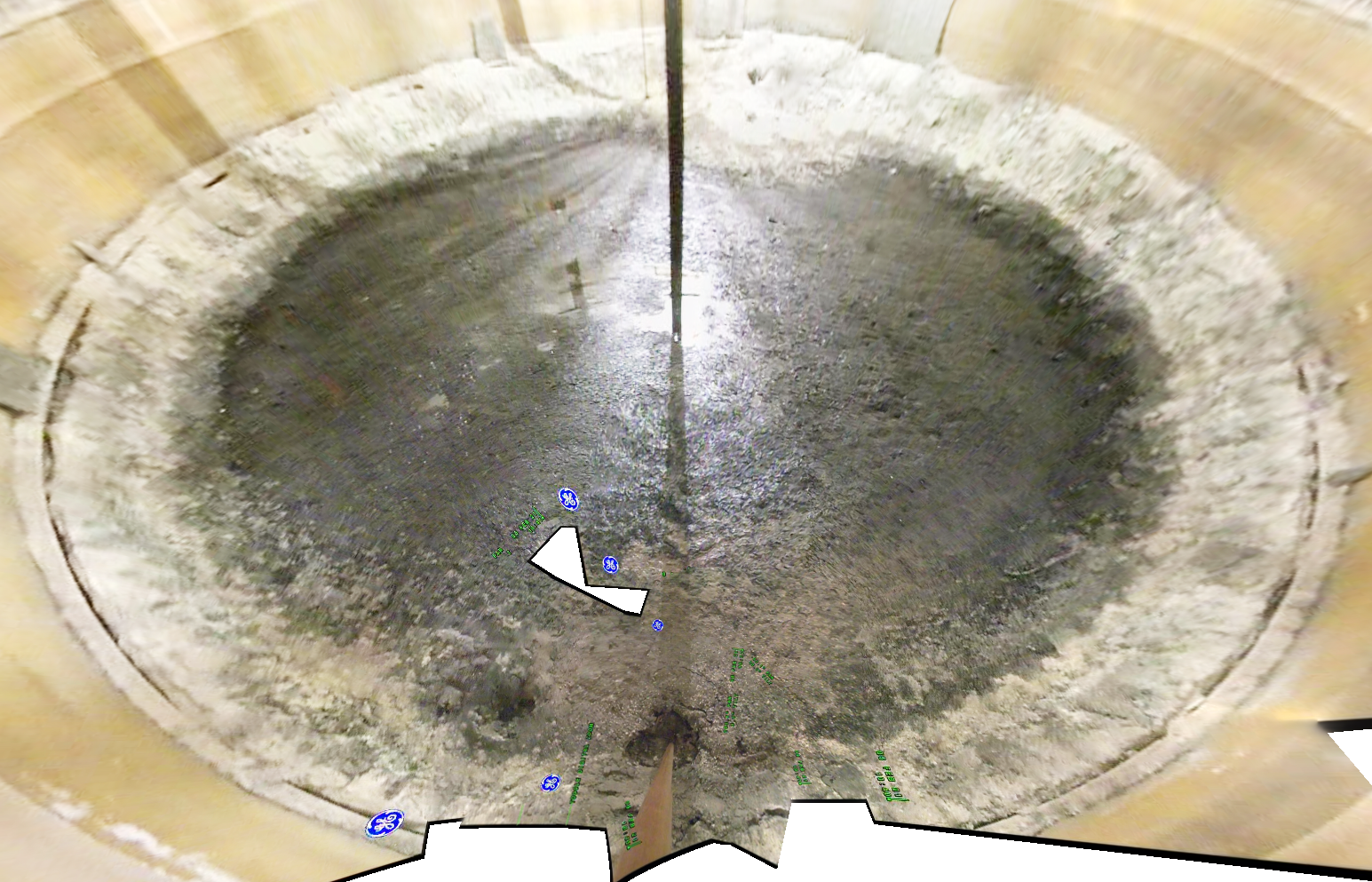

A look at the inside of B-109 in February 2021.

Following the Tank B-109 leak announcement, we pursued this legally-binding agreement with Energy. The Agreed Order, and its 2024 addendum, define when and how Energy will respond to leaks from the three tanks, and also develops systems and protocols for responding to future leaks.

The Agreed Order requires Energy to:

- Cover the T and B tank farms with surface barriers to prevent rain or snowmelt from seeping into the tanks, and to slow the migration of leaked waste toward the groundwater.

- Evaluate the viability of installing a ventilation system to evaporate liquid waste in Tank B-109.

- Develop a response plan for future leaks from single-shell tanks that will eventually be incorporated into the Hanford Site Wide Permit.

- Evaluate conditions in and around tanks B-109 and T-111 to determine if additional work is needed to prevent rain or snowmelt from getting in.

- Explore ways to accelerate the schedule to retrieve waste from tanks B-109 and T-111.

The T-101 addendum requires Energy to:

- Evaluate conditions in and around Tank T-101 to determine if additional work is needed to prevent intrusions such as rain or snowmelt from getting in the tank.

- Evaluating the feasibility of using active ventilation to evaporate liquid waste in T-101.

- Negotiating a new deadline to retrieve waste from T-101.

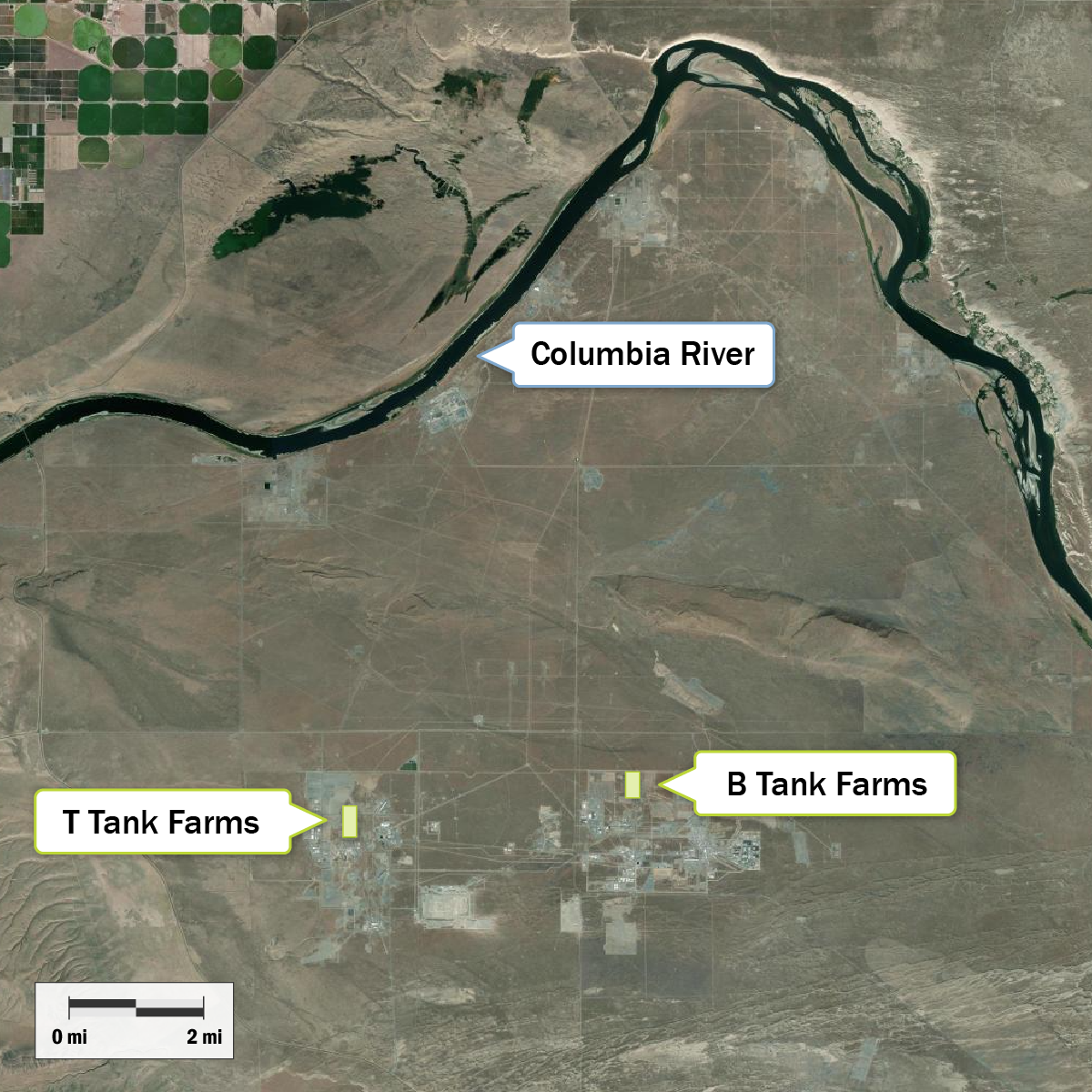

Location of the B and T tanks on the Hanford Site.

Public input

As we implement this Agreed Order with Energy, the public can provide input during the permitting process on the Single-Shell Tank System Leak Response Plan.

Agreed Order appeal settlement

Heart of America Northwest, a nonprofit group, challenged the Agreed Order that our agency and Energy announced last August. The agencies and Heart of America Northwest reached a settlement on the appeal in May 2023.

The settlement with Heart of America does not amend the Agreed Order, but provides clarity on the order’s requirements. It also requires Energy to obtain a third-party expert review from Pacific Northwest National Laboratory of a key technical evaluation included in the order.

We agreed to publish the following language on this web page as part of the settlement agreement:

The Agreed Order requires the U.S. Department of Energy (Energy) to conduct certain

studies or evaluations and submit permit application material relating to responding to leaking

single-shell tanks (SSTs), including a Leak Response Plan and a practicability evaluation. These

two key deliverables are described below.

See additional information about the Agreed Order requirements described above.

As part of the settlement agreement, we also agreed to publish the following statement to clarify the relationship between the Tri-Party Agreement’s requirements for single-shell tank leak detection and the Agreed Order’s requirements for the development of improved leak detection technology.

Background

Frequently asked questions

Contact information

Ryan Miller

Communications Manager

Ryan.Miller@ecy.wa.gov

509-537-2228