Hanford Waste Treatment Plant

We oversee the permitting, construction, and eventual operation of the world’s largest treatment plant for radioactive waste, the Hanford Waste Treatment and Immobilization Plant (WTP). The plant will process radioactive and chemical waste from Hanford's underground tanks into a glass waste form. The glass will keep the waste stable so it can be safely stored and disposed without posing significant risk to human health or the environment.

In June 2002, workers poured the first yard of concrete for Hanford's Waste Treatment and Immobilization Plant (WTP). The facility is intended to treat 56 million gallons of radioactive and dangerous chemical waste currently stored in 177 aging tanks at Hanford. The start of construction culminated more than a decade of planning by the state of Washington and the U.S. Department of Energy. The plan is to build a facility capable of treating the nuclear waste and reducing the risks it poses to humans and the environment.

If the waste is not removed from the tanks and treated, it will eventually escape containment and reach the Columbia River. More than one million gallons of waste already has leaked. The treatment plant is a critical component in the overall Hanford cleanup. It will go a long way toward reducing the threat to the environment and to surrounding communities.

When will the treatment plant begin operations?

A portion of the Waste Treatment Plant is projected to begin operating in 2025. Waste will be removed from aging underground storage tanks and then immobilized in glass through a process called vitrification.

The WTP, also known as the vitrification, or "vit" plant, is the cornerstone of Hanford's cleanup. We are working diligently with Energy and its contractors to promote a timely launch. In the past, we've taken them to court when necessary.

What is vitrification?

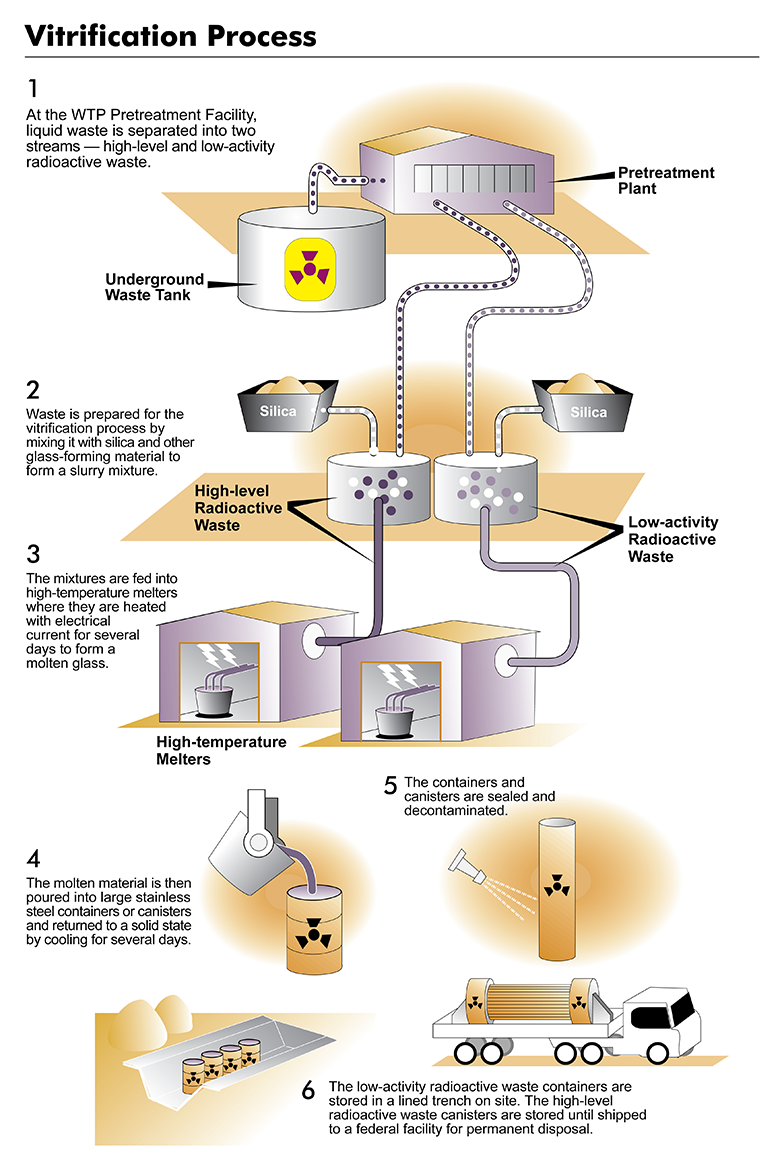

Vitrification is the transformation of a substance into a glass. At the Waste Treatment Plant (WTP), the process converts liquid radioactive and chemical waste into solid waste. The WTP includes the Pretreatment Facility (the largest, with a footprint of about 1.5 football fields), the Low-Activity Waste Vitrification Facility, the High-Level Waste Vitrification Facility, Analytical Laboratory, and other supporting facilities.

The Pretreatment Facility would separate waste into a low-activity waste stream and a high-level waste stream. Those waste streams are forwarded to their respective vitrification facilities, where glass-forming additives are combined with the waste. The mixtures are then heated to about 2100°F and poured into stainless steel containers for eventual storage and disposal.

Direct-Feed Low-Activity Waste

To begin treating waste by 2025, Energy is pursuing a process called Direct-Feed Low-Activity Waste (DFLAW) which will allow for treatment of low-activity waste prior to the Pretreatment Facility being completed. DFLAW requires Tank-Side Cesium Removal, the Analytical Laboratory, Low-Activity Waste Vitrification Facility, and another building under construction on the Waste Treatment Plant site called the Effluent Management Facility.

With DFLAW, tank waste is first pretreated using a Tank-Side Cesium Removal system to separate cesium and solids before being sent as low-activity waste to the Low-Activity Waste Vitrification Facility for treatment. Liquid effluents generated at this facility and at the Analytical Laboratory will be transferred to and treated at the Effluent Management Facility, which will reduce the effluent volume by evaporation.

Once the rest of the Waste Treatment Plant's facilities become operational, both low-activity and high-level waste treatment will undergo the originally planned process.

Related links

Contact information

Ryan Miller

Communications Manager

Ryan.Miller@ecy.wa.gov

509-537-2228