Kaiser Aluminum’s Trentwood facility is in the early phases of testing new technology that destroys over 90 percent of polychlorinated biphenyl (PCB) contamination in water at their facility in the Spokane Valley.

The Trentwood facility has produced specialized aluminum products for more than 75 years and, like many facilities around the country, used PCB-containing oils in an effort to safely and efficiently operate some industrial equipment. Over the years, some of the PCB oil leaked, contaminating groundwater under the aluminum-casting building near the Spokane River.

Kaiser has been researching and implementing technologies to address the contaminated groundwater, and is now examining two processes to see which will more effectively reduce the threat posed by the PCBs.

Walnut shells and castor oil, or ultraviolet light and hydrogen peroxide?

The walnut shell and castor oil system Kaiser's operated since 2015 removes 70 percent of PCBs from water.

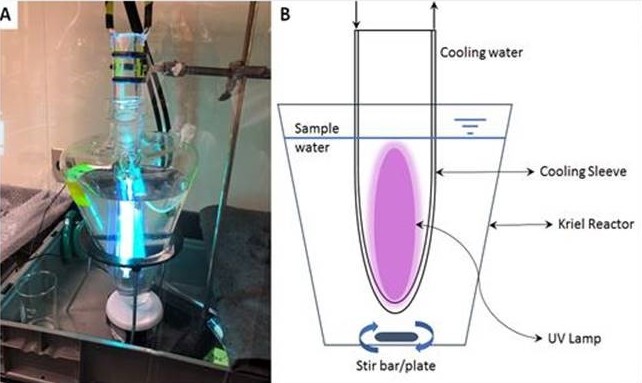

Before drafting the plan for full-scale cleanup, we asked Kaiser if any new technologies might be available to more effectively treat the groundwater contamination. A few weeks later, Kaiser sent us research that showed PCBs in water could be destroyed using ultraviolet (UV) light and a little hydrogen peroxide. We agreed to wait until they could determine which technology worked better and was more cost effective.

Kaiser first first started testing in a bench-scale format to replicate exactly what was in the research.

Ecology’s site manager Jeremy Schmidt recently visited the facility and answered questions about the cleanup for Inlander reporter Samantha Wohlfeil. You can learn more in her Nov. 25 article “Kaiser Aluminum experiments with a new way to break down toxic chemicals” and on our Kaiser Aluminum cleanup website.

The deadline to decide on the final cleanup method is February 2022, and Kaiser will implement a full-scale cleanup system within a year after.