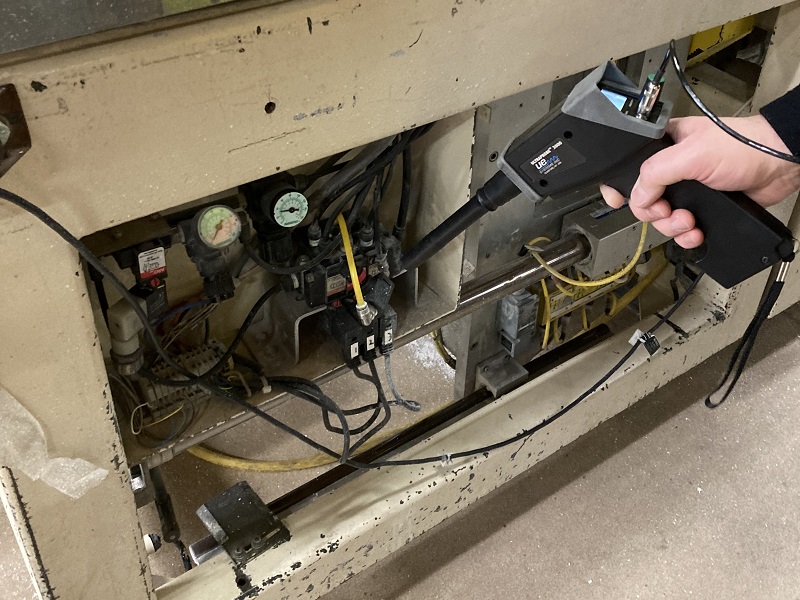

An Ecology environmental specialist uses ultrasonic detection equipment to find a compressed air leak at Mikron. Reducing air leaks benefits both businesses and the environment.

Many industrial processes, such as machining, painting, and extrusion, use compressed air. Generating and using compressed air can account for 10% to 30% of energy consumption at an industrial facility. Leaks in compressed air lines can significantly impact a facility’s energy use and utility costs.

Mikron Industries, a subsidiary of Quanex in Kent, Wash., manufactures PVC window and door fixtures using an extrusion process. Compressed air is used to displace PVC through the molds in the extruders to generate custom shaped parts. Mikron worked with us to complete a compressed air leak audit, a free Pollution Prevention Technical Assistance service we offer to identify hidden and inaudible leaks in compressed air lines using ultrasonic detection equipment.

Identifying these leaks can be tricky. A few leaks may be easy to find — they can be heard by the human ear and immediately repaired. However, most leaks are inaudible and require special ultrasonic equipment to identify and repair them. During a compressed air leak audit, our trained experts use this equipment to quantify the amount of air lost through each leak. Then we give the business a cost savings estimate based on the total number of leaks found during the audit. At a site with extensive compressed air lines like Mikron Industries, many small leaks add up to substantial energy consumption.

During Mikron Industries’ audit, we identified 51 inaudible and five audible compressed air leaks in roughly two-thirds of the facility. We estimated a savings of $13,000 per month, or $157,000 per year, should all identified leaks be repaired. Mikron Industries continues work to repair leaks, and initial utility bills show an approximate 20% reduction in power consumption between the same month in 2022 and 2023, which results in significant energy and cost savings.

Ecology’s Pollution Prevention Technical Assistance services provide non-enforcement technical assistance to Washington businesses. Our engineers, chemists, toxicologists, and environmental specialists can help businesses reduce operating costs, improve energy and water use, and more. To learn more about this project, contact Toxics Reduction engineer Westley McKane at 206-659-2226 or westley.mckane@ecy.wa.gov. Visit our Toxics Reduction Team website to learn about our team.